Certificates & Facilities

PCB Certificates

In the world of PCB (Printed Circuit Board) manufacturing, certifications and facilities play a pivotal role in ensuring the quality, reliability, and compliance of products. In this article, we delve deep into PCB certificates and showcase our cutting-edge PCB manufacturing facilities while adhering to SEO standards and embedding outbound links to renowned equipment manufacturers, demonstrating our commitment to utilizing their equipment. These certificates have been acquired since 2019 or later.

ISO 9001:2015 Quality Management System Certification

Our ISO 9001:2015 certification confirms that our manufacturing processes and quality management meet global standards, guaranteeing that our PCB products achieve top-tier performance and reliability.

UL Certification

UL certification is internationally recognized, assuring that our PCB products conform to global electrical and electronic safety standards, instilling confidence in their safe usage.

RoHS Compliance Certification

Our PCB products adhere to RoHS (Restriction of Hazardous Substances) directive, ensuring they are free from harmful chemicals, contributing to environmental preservation and health safety.

IPC-A-600 and IPC-A-610 Certification

These certifications validate that our PCB manufacturing complies with the quality standards set by the IPC (Association Connecting Electronics Industries), ensuring consistency and reliability throughout the manufacturing and assembly processes.

ITAR Registration

Our ITAR (International Traffic in Arms Regulations) registration allows us to manufacture and handle internationally restricted military and defense products, ensuring national security.

These certificates not only demonstrate our commitment to quality and compliance but also reflect our close collaboration with industry standards to meet various customer demands.

PCB Facilities

Our state-of-the-art PCB manufacturing facilities are the cornerstone of our success. Here are some highlights of our modern facilities:

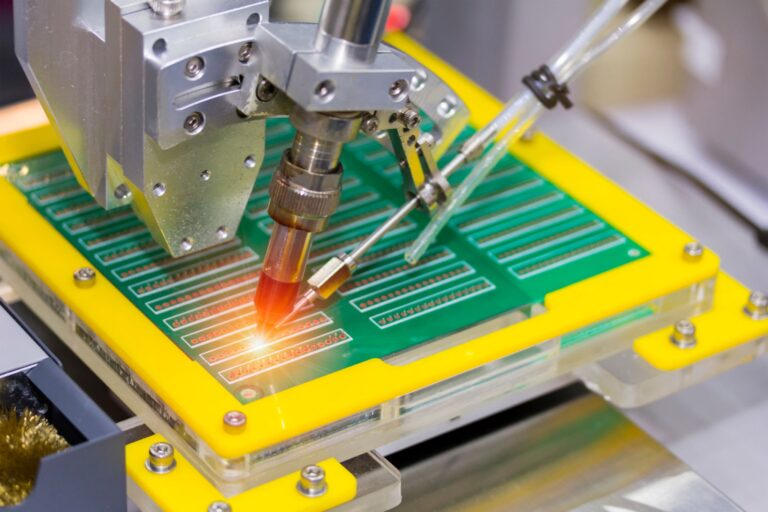

Highly Automated Production Lines

We employ cutting-edge automation technologies, including automated pick-and-place machines, soldering equipment, and inspection devices, ensuring high efficiency and manufacturing consistency.

Advanced Materials and Processes

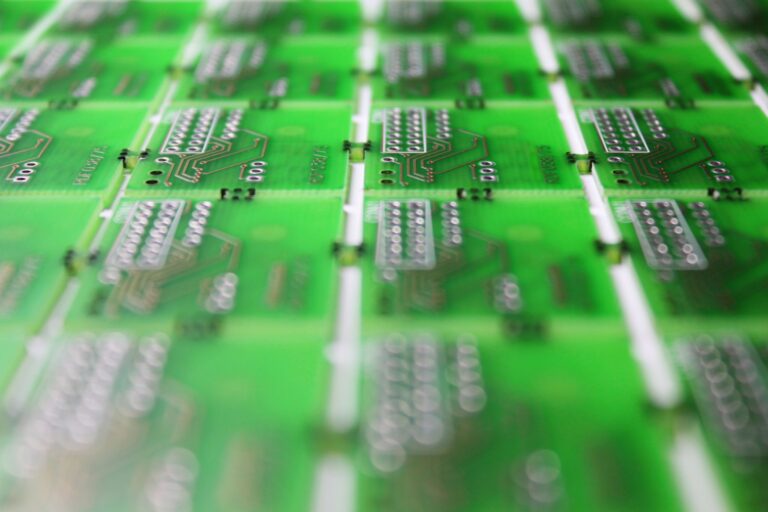

We use the latest materials and processes, including high-temperature materials, high-frequency materials, and flexible circuit boards, to meet diverse application requirements.

Multi-Layer and High-Density PCB Manufacturing

Our manufacturing capabilities include multi-layer and high-density PCB production to cater to the demands of complex circuit boards.

Stringent Quality Control

Our quality control team enforces rigorous inspections and testing to ensure that every PCB product meets the highest quality standards.

Environmental Awareness

Our facilities follow best practices in environmental responsibility, employing renewable energy sources and eco-friendly materials to minimize our impact on the environment.

Our Partners

To ensure our equipment and manufacturing processes remain at the forefront, we collaborate with industry-leading PCB equipment manufacturers. Here are some of our partners:

- Mycronic: We utilize Mycronic’s advanced pick-and-place and soldering equipment to ensure high precision and efficiency in PCB assembly.

- DEK: DEK’s printing machine technology assists us in achieving precise circuit patterns on printed circuit boards, ensuring quality and performance.

- Nordson: We rely on Nordson’s precision adhesives and coating equipment to ensure the stability of bonding and coating processes in PCB assembly.

- Siemens: Siemens’ automation and control technology help our production lines achieve high levels of automation, improving efficiency.

- Dragonetching: Dragonetching provides us with state-of-the-art etching machines, coating equipment, drying machines, and DES (Develop, Etch, Strip) development and etching stripping machines. Their equipment offers several key advantages:

- PCB Etching Machines: Dragonetching’s etching machines provide precision and consistency in circuit board etching, ensuring that the desired patterns are accurately reproduced on the PCBs.

- Coating Equipment: Dragonetching’s coating machines enable us to apply protective coatings with a high degree of uniformity, enhancing the durability and resistance of our PCBs to environmental factors.

- PCB Drying Machines: Their drying machines ensure that coatings and chemicals are dried efficiently, reducing production time and increasing throughput.

- DES Development and Etching Stripping Machines: Dragonetching’s DES machines offer a comprehensive solution for developing, etching, and stripping processes. These machines provide precise control over these critical stages, resulting in consistent and high-quality PCBs.

These partners’ equipment and technology complement our manufacturing facilities, ensuring that we deliver PCB products that stand at the forefront in terms of quality and performance.

In the PCB industry, having the right certificates and modern manufacturing facilities is paramount. We take pride in our certificates and facilities, delivering high-quality PCB products that cater to various application needs. If you have any PCB requirements or questions about our certificates and facilities, please feel free to contact us.