Nelco PCB

Nelco PCBs: Advancing Electronics with Precision

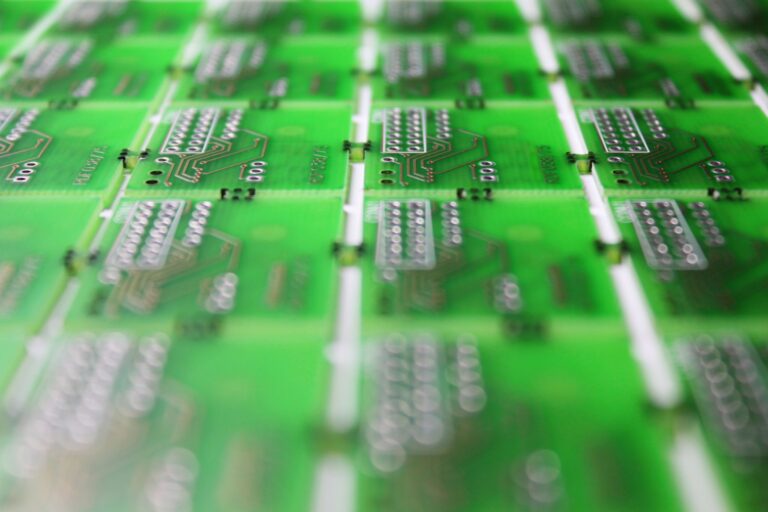

1. Precision with Nelco Material

- Advanced Material: Nelco PCBs are built on a foundation of high-quality materials known for their excellent electrical and mechanical properties, ensuring optimal performance.

- Low Signal Loss: Nelco materials are designed to minimize signal loss, making them ideal for high-frequency applications where signal integrity is paramount.

- Thermal Performance: Nelco PCBs exhibit strong thermal stability, ensuring reliable performance even under extreme temperature conditions.

2. Advantages of Nelco PCBs

- High-Frequency Capability: Nelco PCBs are engineered to handle high-frequency signals with minimal attenuation, making them suitable for advanced communication systems and radar technology.

- Low Dielectric Loss: These PCBs offer low dielectric loss and high-speed signal propagation, meeting the demands of data-intensive applications in telecommunications and aerospace.

- Customizability: Nelco PCBs can be customized to meet specific design and performance requirements, making them adaptable to a wide range of applications.

3. Diverse Applications

- Aerospace and Defense: Nelco PCBs are essential components in military radar systems, satellite communication, and avionics, where precision and reliability are critical.

- Telecommunications: The telecommunications industry relies on Nelco PCBs for high-speed data transmission, ensuring seamless connectivity and network performance.

- Automotive Electronics: In the automotive sector, Nelco PCBs enable advanced electronic systems, including engine control units, infotainment, and safety features.

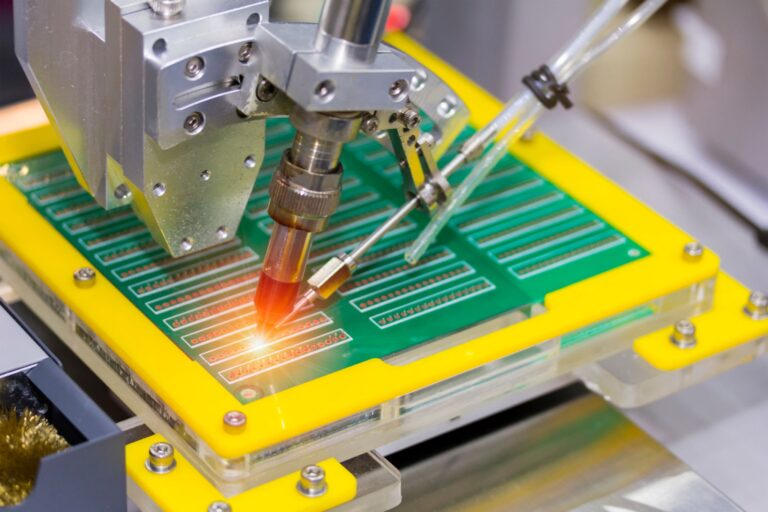

4. Industry-Leading Manufacturing Process

- Stringent Quality Control: Leading manufacturers maintain rigorous quality control measures to produce Nelco PCBs that meet or exceed industry standards.

- Collaborative Design: Engineers work closely with clients to create custom Nelco PCB solutions, ensuring they align with specific project requirements.

5. Commitment to Sustainability

- Eco-Friendly Practices: Many manufacturers prioritize eco-friendly practices, employing lead-free materials and sustainable production processes in the manufacturing of Nelco PCBs.

- Recyclability: Nelco PCBs are designed with recyclability in mind, contributing to a more sustainable electronics industry.

Nelco PCBs continue to be at the forefront of electronic advancements, offering reliability and performance that powers critical applications across various industries. Whether you’re working on aerospace, telecommunications, or automotive projects, Nelco PCBs are a trusted choice for high-precision electronic needs.

For more information about Nelco PCB technology or to discuss how it can enhance your project, please don’t hesitate to contact us. We’re here to provide guidance and support for your electronic endeavors.